MorphingSkin: A Skin-like Platform that Integrates Multimodal Hydraulic Actuators Based on Flexible Electroosmotic Pumps

2024-2025

Download Media Package

In this work, we present MorphingSkin, a skin-like platform that integrates multiple, multimodal hydraulic actuators using flexible EOPs as lightweight and self-contained fluidic actuators. We introduce the architecture of MorphingSkin and its versatile design space for multimodal actuation in force, shape, optical, and weight domains. We demonstrate interactive and robotic applications that integrate multiple actuators working collectively within a single MorphingSkin device. Through this work, we envision the future of using MorphingSkin technology for interactive surfaces that integrate flexible form factors and multimodal actuation capabilities.

Tianyu Yu, Peisheng He, Bob Tianqi Wei, Chenyuheng Wang, Xueqing Li, Xuezhu Wang, Yao Lu, Wei Yue, Megan Teng, Zihan Wang, Liwei Lin, Haipeng Mi, Qi Lu, Lining Yao

In ACM User Interface Software and Technology Symposium (UIST). 2025. PDF | DOI

🏆 Best Paper Award

MorphingSkin Overview

MorphingSkin is a skin-like platform that integrates multiple, multimodal hydraulic actuators using flexible electroosmotic pumps (EOPs) as lightweight and self-contained fluidic actuators. As fluid has enabled multimodal physical dynamics in nature—changing body shape or appearance, or transmitting nutrients—for millions of years, we explored the multimodal actuation capabilities of MorphingSkin in force, shape, optical, and weight domains, and envision the technique as a candidate for future computing devices with interactive surfaces. We then demonstrated applications through various fields, including robotic skins, multimodal wearables, and tangible displays.

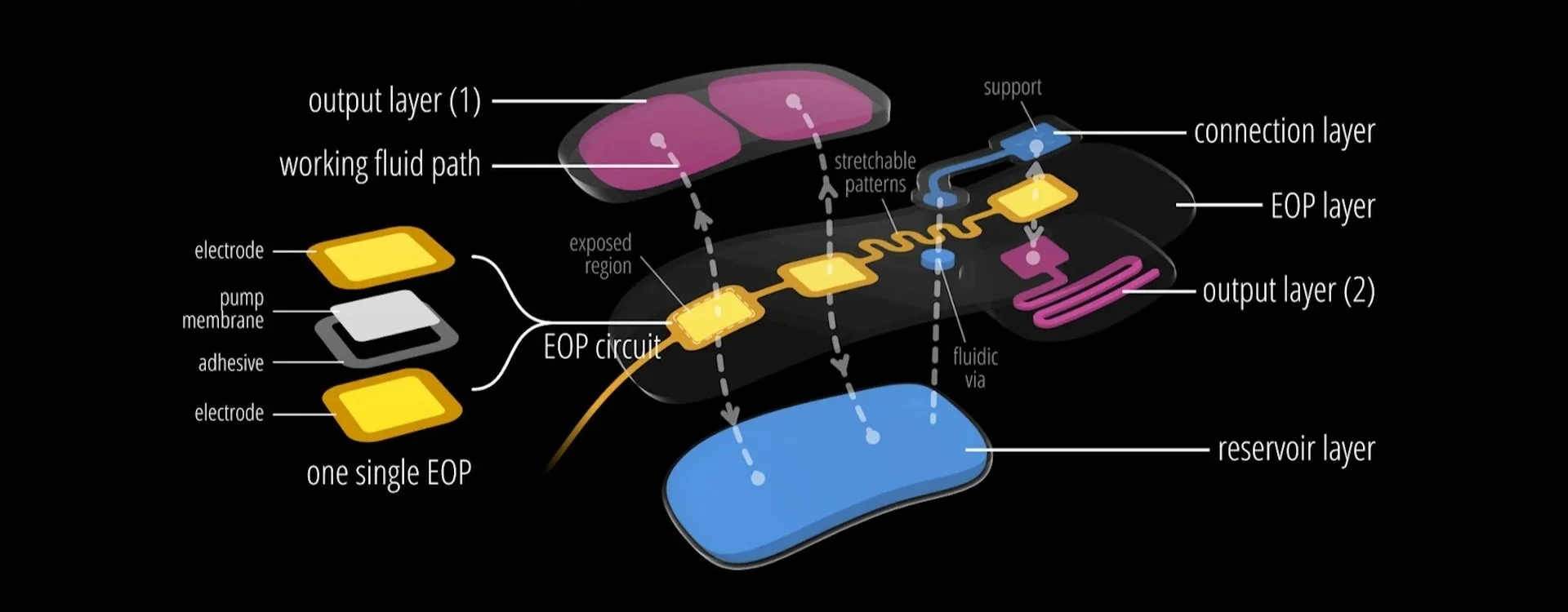

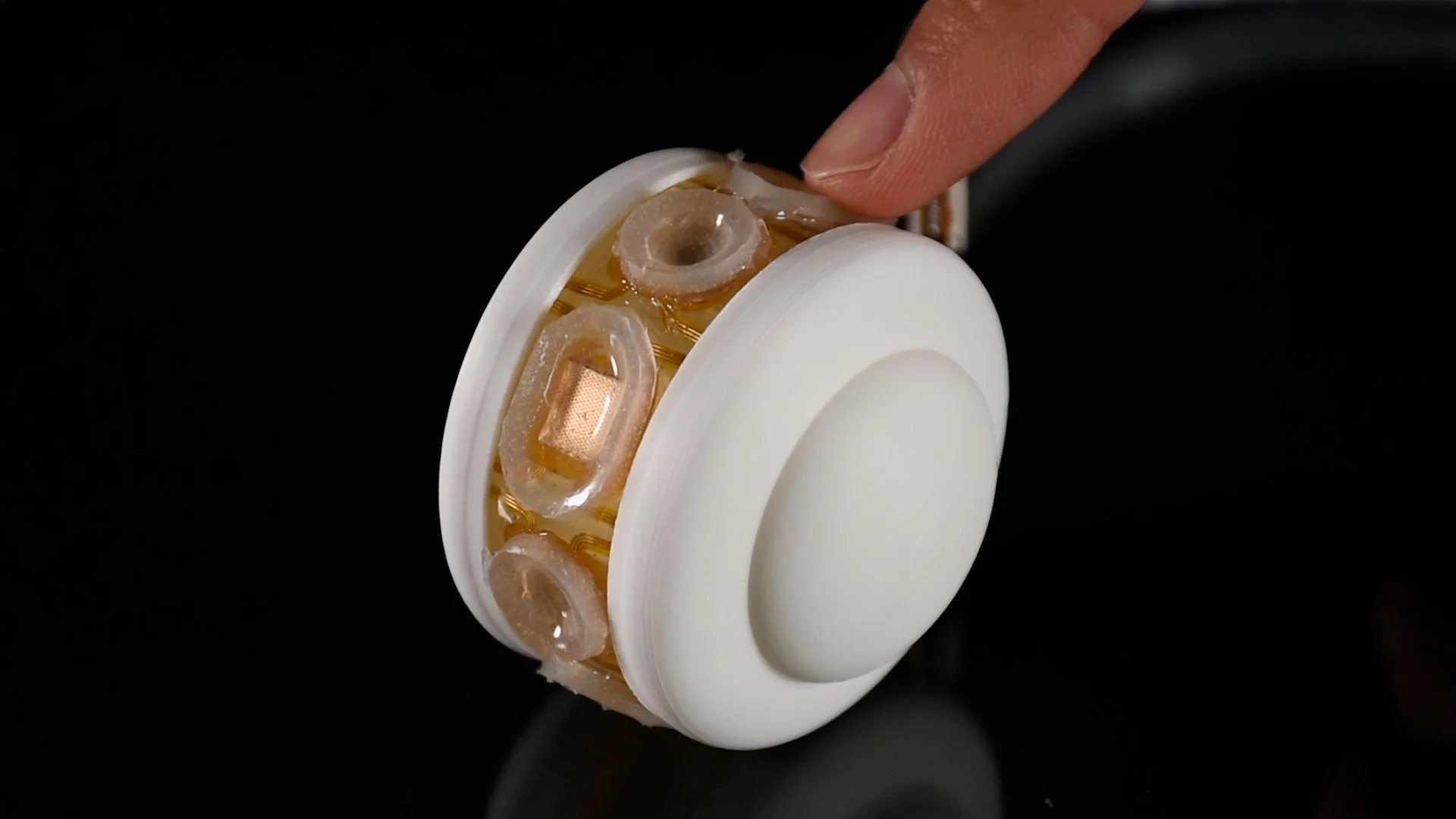

MorphingSkin Composition

Morning skin composition is centered with a flexible EOP circuit. The circuit is designed using flexible printed circuits and adopts stretchable patterns. The circuit is then coated with a layer of stretchable material, such as silicone, to form a continuous, stretchable middle layer. Next, different elastic shells are designed and bonded on both sides of the middle layer, to serve different functions, such as output actuators, or reservoirs. Lastly, working fluid is enclosed inside, pumped by the EOPs across different layers to output actuation.

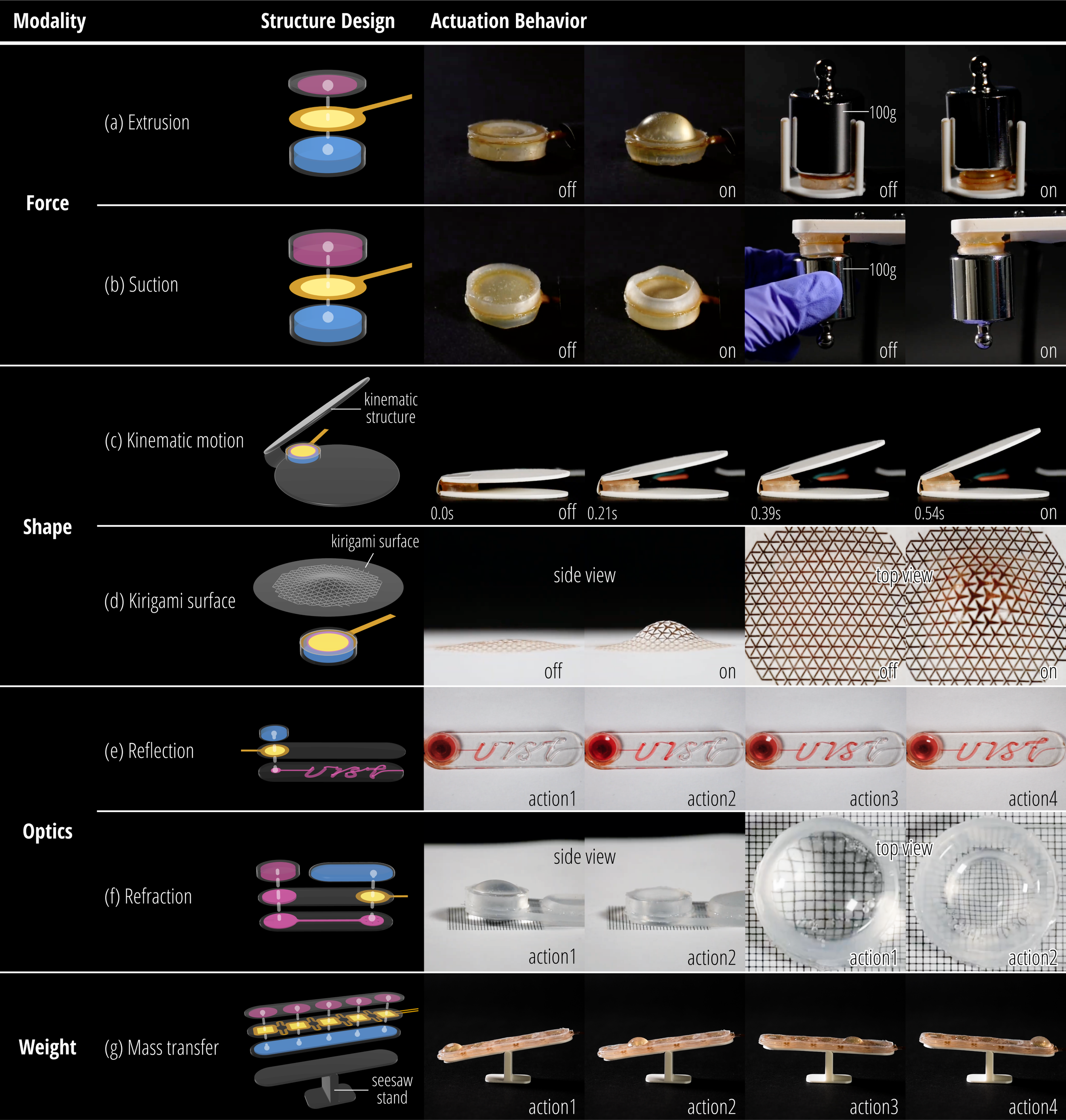

Multimodal Actuation Design Space

By varying the design of the multilayer structures, MorphingSkin achieves a versatile design space for multimodal actuation, spanning force, shape, optical, and weight domains. This multimodal actuation design space enables various combinations for different application opportunities.

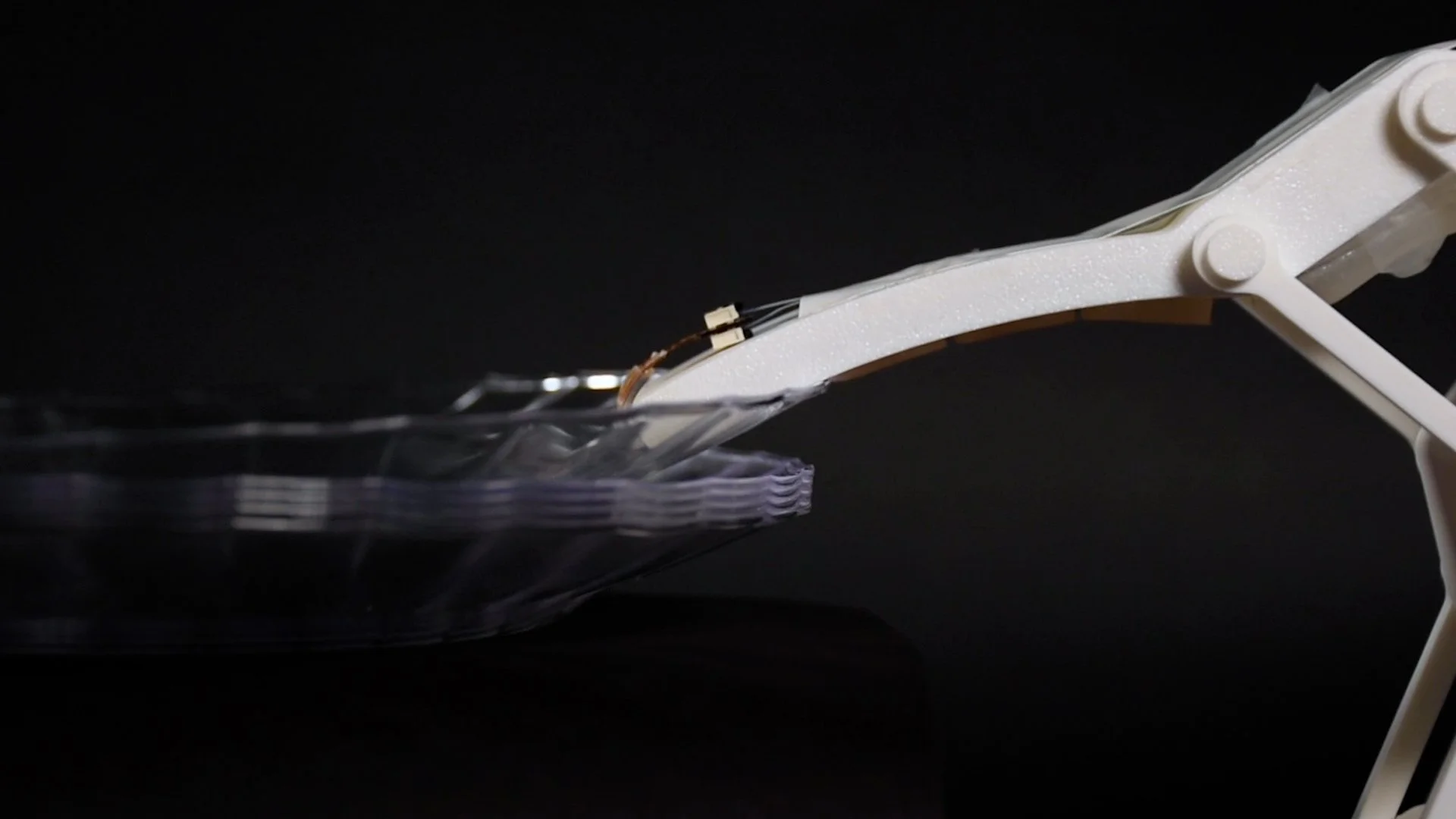

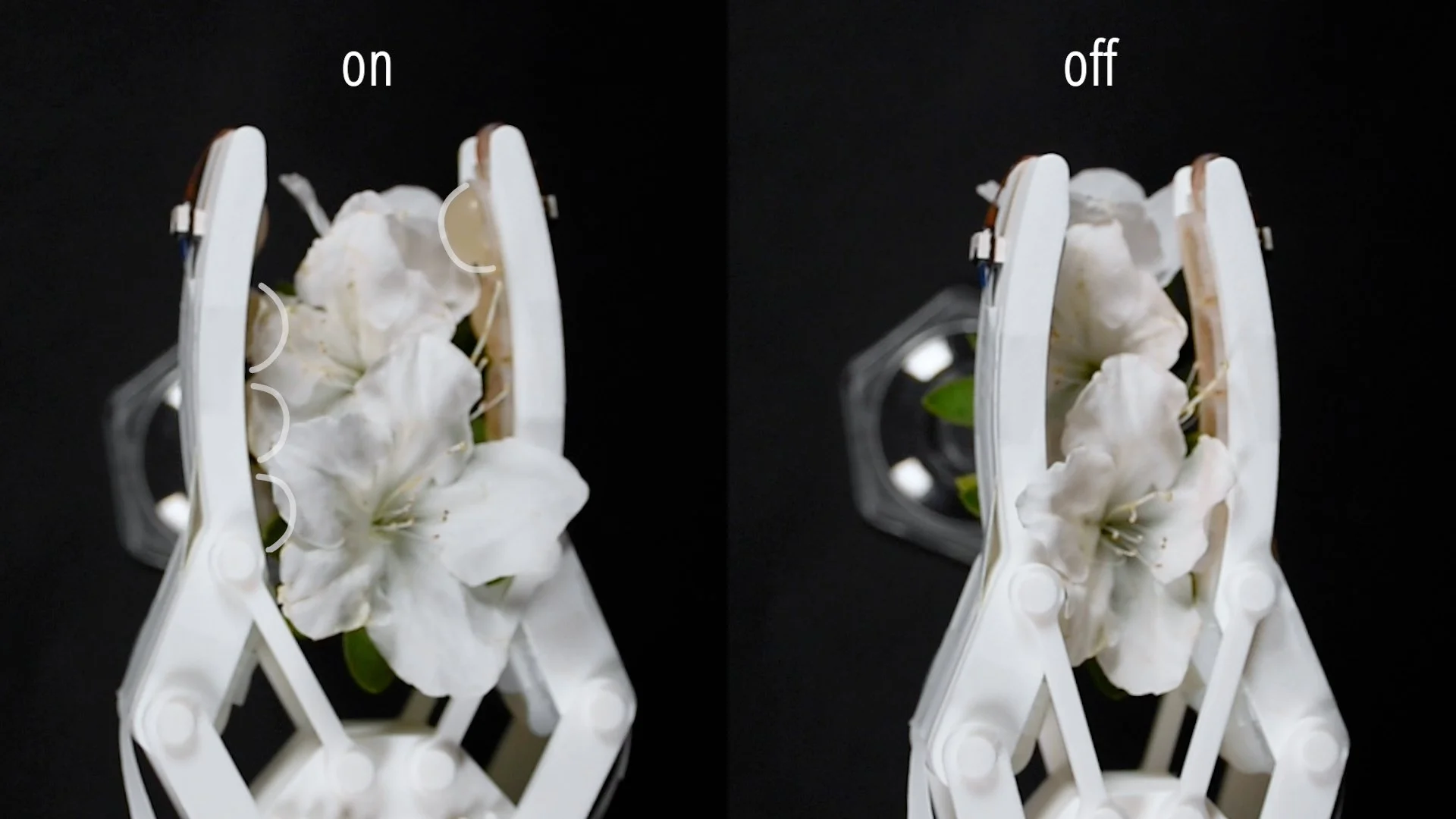

Application 1: Dynamic Contact Condition for Robot Skin

The first prototype demonstrates a robotic gripper that can provide extrusion or suction actuation on the skin. These can be used to adapt to different mechanical sensitivities of the object.

For example, by selectively actuating the extrusion actuators, the gripper can provide a shape-adaptive, localized soft contact, to grip a rectangular cake, instead of crushing the corner of the cake. It can also grip some fragile objects, such as flowers, by providing localized soft support, to avoid squeezing the flowers.

For suction contact (left two figures), the gripper can perform suction on objects that are challenging to pinch, such as a fragile chocolate or a plate stacked on top of the others. If the skin remains inactive, it can also provide a larger gripping force by hard contact (right two figures) from the backbone, in order to hold some solid and heavy objects.

Application 2: Desktop Companion Robot

Another robotic application we demonstrated is this desktop companion robot. It can collectively use the extrusion and suction actuators around the body to provide highly emotional expressions.

For example, it can mimic an inflating breathing rhythm to show a calm mood (figures 1,2), or move itself around the table by excursion, to show excited emotion (figures 3,4). It can also stick to the table by suction, like being frozen on the table, to mimic a frightened feeling (figures 5,6), or stick to other objects from the user, as if it is playing with the user in a mischievous mood (figures 7,8).

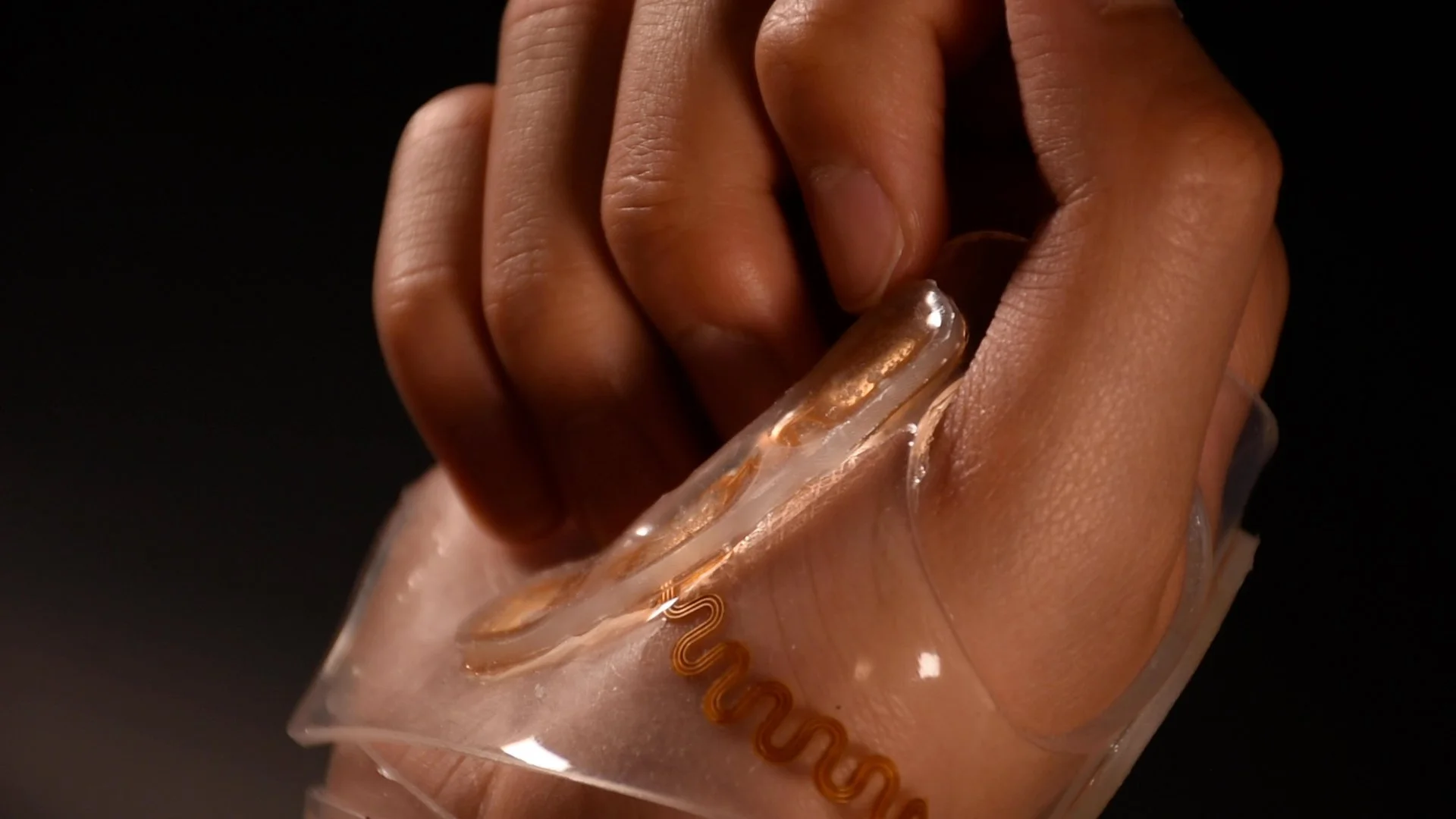

Application 3: Multimodal Wearables

To explore using MorphingSkin as a wearable on the human body, we demonstrate a wrist brace that contains multimodal haptic and visual feedback.

The haptic feedback (left two figures) comes from the extrusion actuators that can provide pressing force inward on human skin. They can also work independently to convey complex spatio-temporal haptic cues. The visual feedback (right two figures) relies on the fluidic display embedded in the brace. They can be controlled by the user, for example, to record information for customized usage.

Based on these functions, we envision application scenarios such as exercising, where users can “feel" the guidance of different actions by haptic feedback, such as the moving direction of their hand or the breathing rhythm. The visual feedback can also provide data visualization, such as heart rate or training progress, in an unobtrusive way.

Application 4: Multimodal Tangible Display

We demonstrate a pop-up book on human anatomy with a “magic page” (figure 1) designed with MorphingSkin. Different actuation modals are used to collectively show the physiological dynamics of the respiratory system. This includes the flow animations (figure 3,4) to mimic the breathing air, the shape movement (figure 5,6) to show the expansion of the lung, and the dynamic refraction lens (figure 7,8) to visualize the expansion of the alveoli.

Application 5: Dynamic Aesthetic Lampshade

The lampshade contains a series of shape-changing lenses (figures 1,2). By using their shape changes and their interaction with light, we can achieve many different illumination effects, such as dynamic light patterns on the ground (figures 3,4), ambient display on the lampshade (figures 5,6), or surface texture changes for aesthetic purposes (figures 7,8).

Fabrication of MorphingSkin

The first step in fabrication is to assemble the flexible EOP circuit. Here, two electrodes sandwich a piece of pump membrane and a TPU adhesion layer, and then are heat-pressed to bond and form the basic electroosmotic pump structure. Next, we coat the EOP circuit with a layer of stretchable material, such as silicone, to provide the continuous, stretchable middle layer. Here, we use masks on both sides to protect the pumping area from being coated. We also dispense glue to enhance the bonding between the circuit surface and the coating silicone. After coating, we fabricate the elastic shell components for outputs and reservoirs. These shells can be made with silicone injection molding and bonded to the EOP layer with glue. For the last step, we use a needle to inject the working fluid and eliminate the air bubbles. After that, the device is completely fabricated, showing flexibility and stretchability.

Technical Evaluation

In this project, we also evaluated a few technical performances of the MorphingSkin devices, including the open flow rate and blocked pressure of the electroosmotic pumps, the power consumption and durability of a typical actuator, and the stretchability of a linear strip-like device. For more details, please refer to our paper.