EpoMemory: Multi-state Shape Memory for Programmable Morphing Interfaces

2022-2023

Smart shape-changing materials can be adapted to different usages, which have been leveraged for dynamic affordances and on-demand haptic feedback in HCI. However, the applicability of these materials is often bottlenecked by their complex fabrication and the challenge of programming localized and individually addressable responses. In this work, we propose a toolkit for designing and fabricating programmable morphing objects using off-the-shelf epoxies. Our method involves varying the crosslinker to epoxy resin ratio to control morphing temperatures from 40 °C to 90 °C, either across different regions of a shape memory device or across devices. Functional components (e.g., conductive fabric, magnetic particles) are also incorporated with the epoxy for sensing and active reconfiguration. A toolbox of fabrication methods and a primitive design library are introduced to support design ideation and programmable morphing. Finally, we demonstrate application examples, including morphing toys, a shape-changing input device, and an active window shutter.

By Ke Zhong, Adriane F. Minori, Di Wu, Humphrey Yang, Mohammad F. Islam, Lining Yao

In ACM Conference on Human Factors in Computing Systems (CHI '23) 2023 | DOI | PDF

Multi-state Shape Memory

We leverage epoxy’s multi-state reprogrammability and inherent material properties to explore design opportunities enabled by our method. The ability to program localized responses allows us to create objects that can locally and/or sequentially transform.

We present the simple yet effective method of introducing multiple controllable glass transition temperatures (Tg) to the same epoxy to achieve conditional and sequential control of multi-stable shape memory and reconfiguration.

The Tg of epoxy can be tuned from 27 °C to 79 °C by changing the mixing ratio between the crosslinker (EPIKURE Curing Agent 3380, Hexion) and the resin (EPON Resin 828, Hexion) from 3:10 to 6:10, respectively.

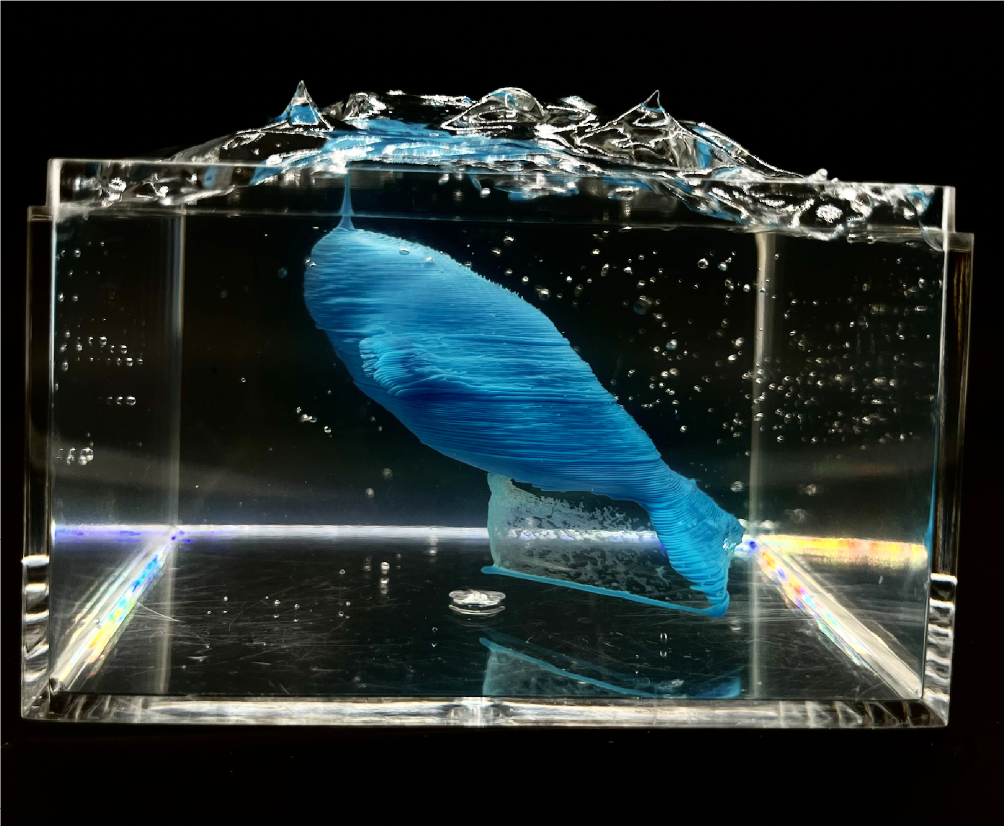

Fabrication Strategies

Fabrication strategies, from molding/casting, laser cutting, to embedded 3D printing, have been explored with epoxy. Here shows the embedded printing process of a whale.

Functional Composites

Using epoxy as the backbone material for shape-changing interfaces also enables the possibility to integrate functional components into the devices to provide additional I/O features.

We explore integrating magnetic particles into the shape-memory epoxy to induce magnetic responsiveness. As illustrated below, the composite is rigid under room temperature and does not deform with external magnetic fields. Yet, when the epoxy is heated, the stripe becomes soft and is bendable by a permanent magnet. The stripe can be locked in its deformed shape by cooling below its Tg. By incorporating functional magnetic particles, we can control temporary shape changes at relatively high temperatures without requiring manual manipulation.

In addition to additive particles, the epoxy can also be composited with onboard circuits for sensing. The device consisting of epoxy and four capacitance sensing buttons can be used as both a gamepad when fat or as a wearable computing interface when wrapped around the human body. Specifcally, when the epoxy is heated, the fabric patches can deform along with the epoxy sheet and conform around an object.

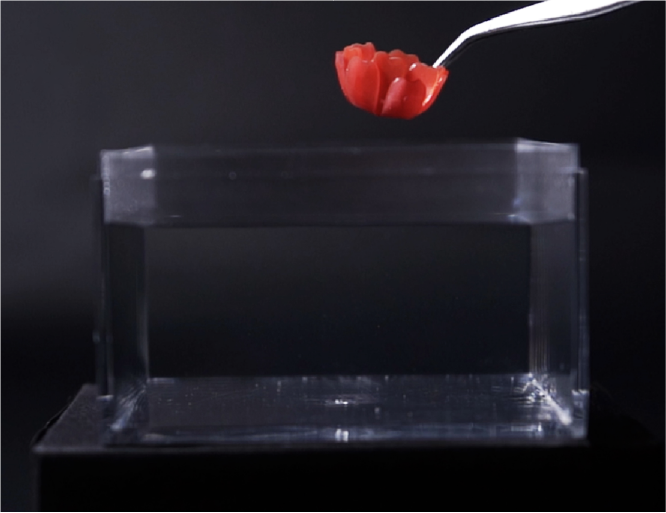

Application: Morphing Toys

Leveraging the shape memory effect, we made two interactive toys with epoxy: a whale and an octopus. The toys are fabricated with the embedded printing method and the printed shape was programmed as their permanent default state. The toys can be deformed or manipulated into different shape-states and recover to their printed shape when placed in a hot water bath without external loads.

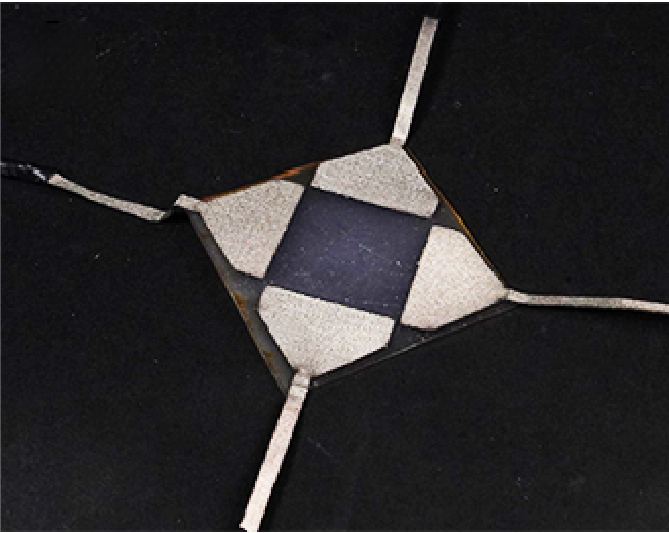

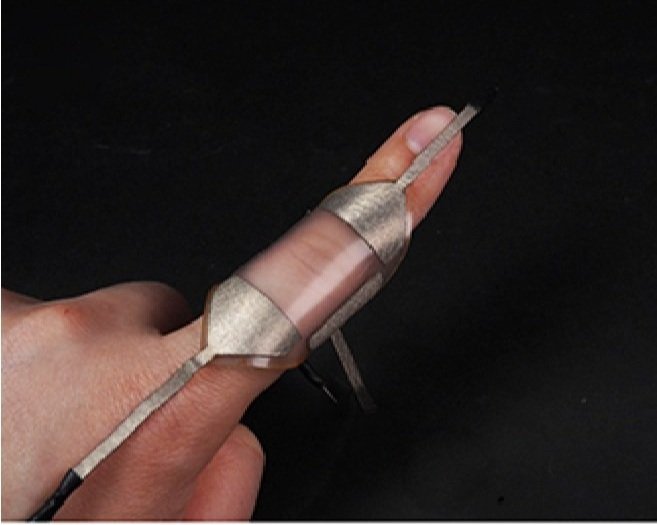

Application: Shape-Changing Input Device

We prototyped an input device that can change shape between three functional modes: a planar controller, a wearable, and a one-handed controller.

The device’s first mode is a planar controller with four buttons integrated for capacitive sensing. When heated to the activation temperature of 60 °C, only the corresponding part will transform, and the device will become a wearable controller that conforms to the forearm and hand. If we heat the device further to 85 °C, the top part can be activated and transformed into the third mode, a one-handed controller. The controller provides three sensing buttons when held in the user’s hand.

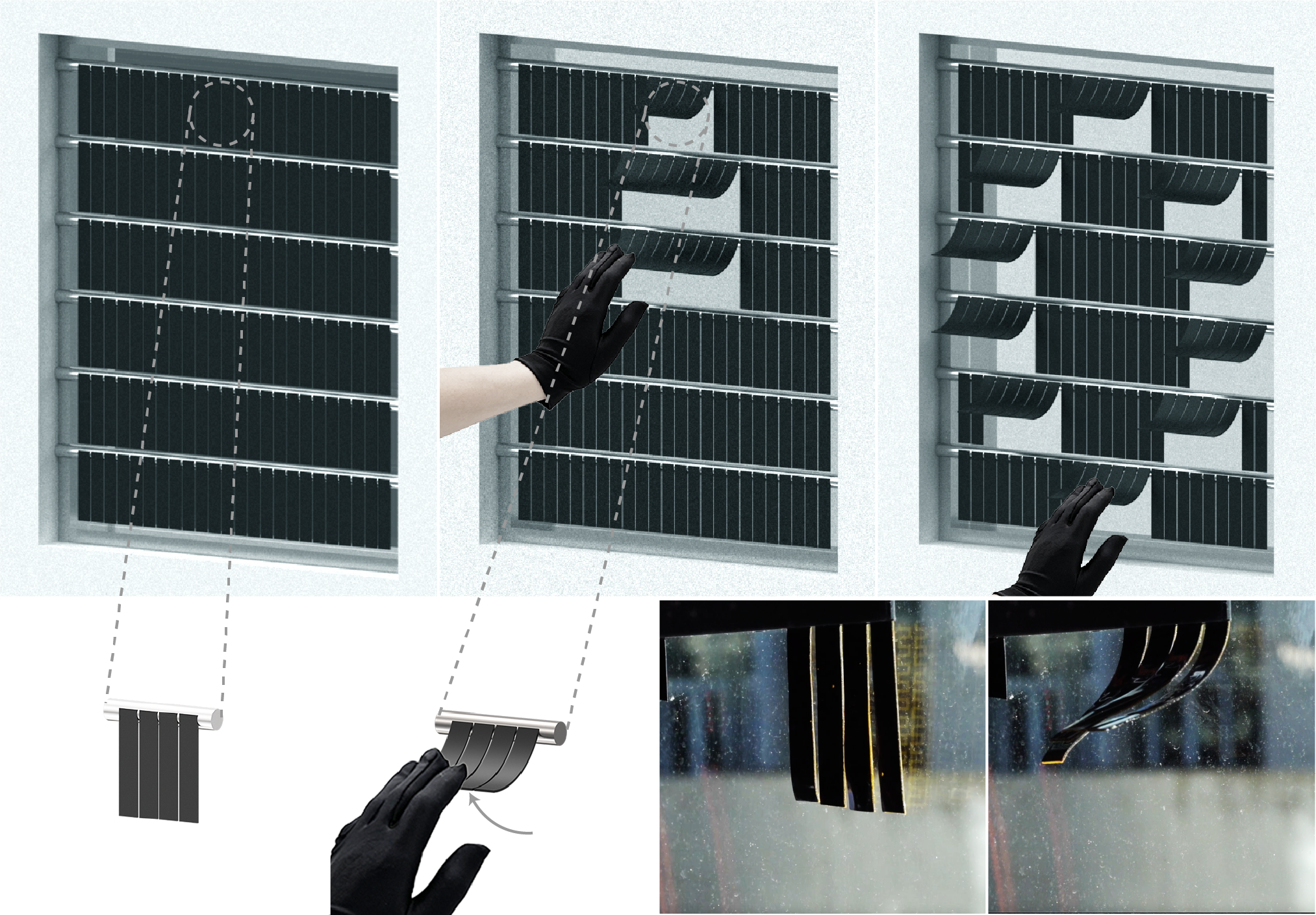

Application: Interactive Window Shutter

The epoxy composite can also be used to make everyday objects more interactive. We create an interactive window shutter consisting of an array of magnetic composite stripes. The units are designed with a fat permanent shape, so the shutter is closed by default. The units’ opening and closing are controlled by a magnetic glove.

Full Video

Acknowledgment

This research was supported by the National Science Foundation Grants (Career IIS2047912 and IIS-2017008), and the College of Engineering at Carnegie Mellon University (Moonshot program/grant 4d6f6f6e73686f74). Adriane Fernandes Minori is a fellow supported by the National Science Foundation under Grant #2127309 to the Computing Research Association for the CIFellows 2021 Project. The authors would also like to thank all the members of Morphing Matter Lab for their support and willingness to brainstorm ideas, Bo Lei, Peter Cheng, and Kunyao Jiang for their insightful discussion and technical support.