A-line:

Printing Morphing Linear Composite Structures

We present A-line, a 4D printing system for designing and fabricating self-folding three-dimensional shapes out of simple linear elements. In addition to the commonly known benefit of 4D printing to save printing time, printing materials, and packaging space, A-line also takes advantage of the unique properties of thin lines, including their suitability for compliant mechanisms and ability to travel through narrow spaces and self-deploy or self-lock on site.

Guanyun Wang*, Ye Tao*, Ozguc Bertug Capunaman, Humphrey Yang, Lining Yao (* Contributed Equally)

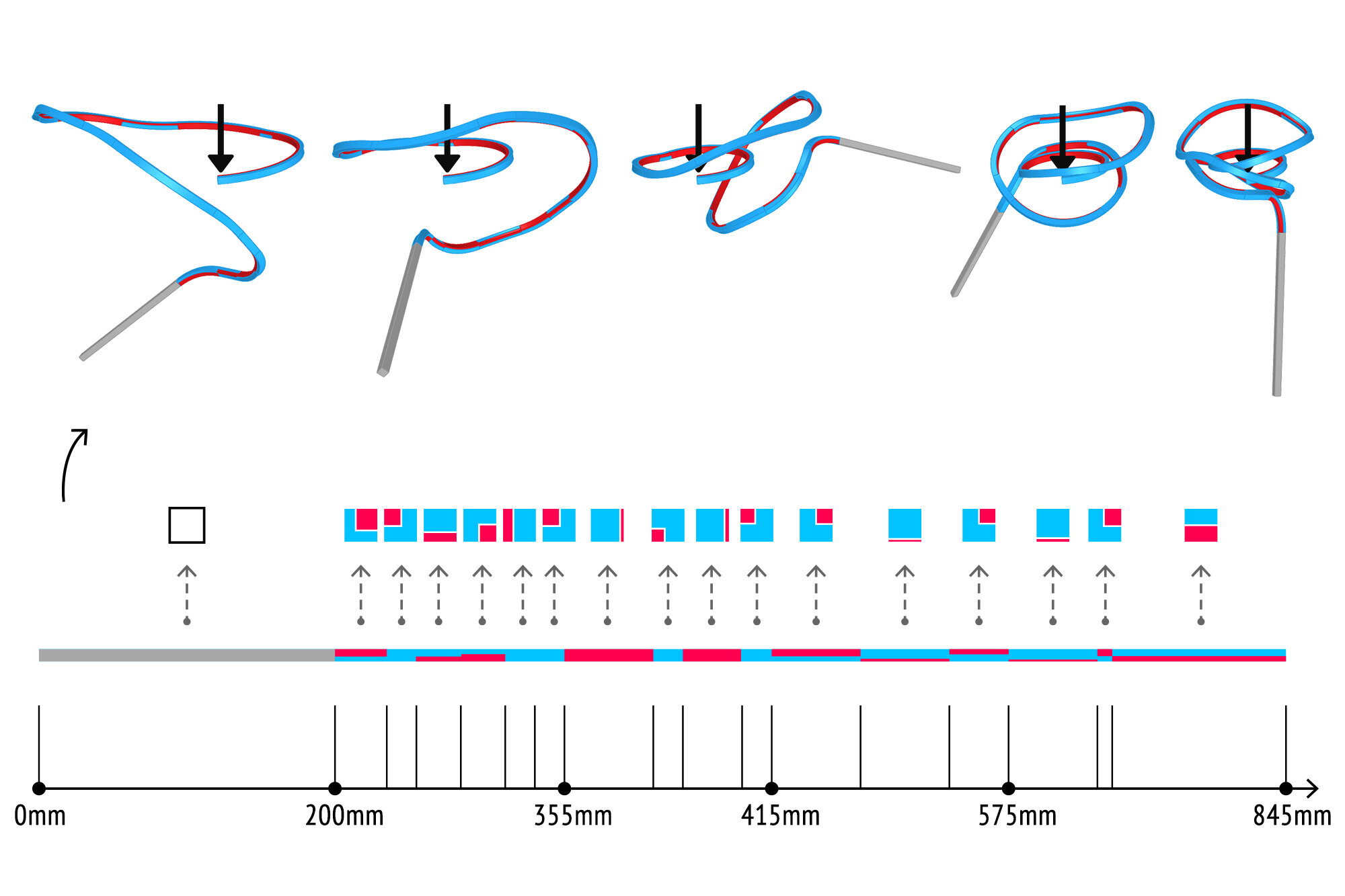

A-line software uses Rhinoceros 6 as the design environment and Grasshopper as both a computational tool and an intermediary user interface. In general, the user workflow is: choose a library model or input a customized curve; define the number of segments and specify the length and actuation behavior for each segment; preview the transformation and generate the printing file.

Sculpting of Line-based Structures

A-line provides designers and artists with a method to produce line-based artifacts.

Self-deployable and Self-locking Structures

One of the advantages of linear structures is that they can enter places where ordinary structures cannot reach, and then trigger its deformation for specific requirement (e.g., self-deployment and self-locking on site).

Compliant Mechanisms of Line-based Structures

A-line has a rich space for designing line-based compliant mechanisms in 3D. Compliant structures like twisting ties and springs are often difficult to make with an FDM printer as the object may fracture at the layering seams, and the support materials are hard to remove as the thin-line form factors make the whole structure fragile. Printing these objects with our techniques, the springs require no support and the seams are aligned with the curved structure and thus difficult to break. Leveraging these benefits, we designed a few compliant mechanism structures including twisting ties, springs, forceps, hairpins, knots, and clips.

A-line has a rich space for designing line-based compliant mechanisms in 3D. Compliant structures like twisting ties and springs are often difficult to make with an FDM printer as the object may fracture at the layering seams, and the support materials are hard to remove as the thin-line form factors make the whole structure fragile. Printing these objects with our techniques, the springs require no support and the seams are aligned with the curved structure and thus difficult to break. Leveraging these benefits, we designed a few compliant mechanism structures including twisting ties, springs, forceps, hairpins, knots, and clips.